Blog

Applications of Nylon Vacuum Bag Film Pre-cutting Machine

Vaccum bag film is a kind of composite nylon resin film, which is broadly applied in areas of wind power, ship-building industry, high speed train, etc. LEAP MACHINERY has developed a new generation of vacuum bagging film pre-cutting machines according to customers’ specific requirements. Pre-cut machines are able to cut nylon vacuum bag materials into conical or trapezoidal shapes, greatly improve production efficiency and reduce material waste.

Applications of Nylon vacuum bagging film

Vacuum bag laminating films are usually nylons, is a type of very cheap materials, many stretch films exist, however most of them are fragile films, and easily punctured. nylon films can be applied in the aerospace and automotive industries to create composite parts. In medical industry, can be used in process of manufacturing prosthetics and implants. In construction industry, it can build waterproof and airtight structures. In food industry, it can creat vacuum-sealed packages. Vacuum bag membranes can be used in the wind power industry to protect components from moisture, dust, and other environmental contaminants, provide insulation and avoid noise, reduce the risk of lightning strikes and ice formation on the blades.Vacuum bagging membranes are produced via co extrusion blow molding machines, then cut into rolls with certain width and length based on the order request.

In vacuum infusion technique for wind power blades, after adding additional materials and other auxiliary materials on the mold, the film is cut to the full size of mold and layed on it. Then fix the vacuum bag film with sealant strip. Its excellent barrier can maintain the pressure of the system well. The same method can also be applied to canoes.

Vacuum bag film pre-cut machines for wind power blades

The shape of wind turbine blades gradually narrows from the root to the tip. Therefore, the size of bag film should guarantee to meet the widest part of the blade during the shaping and laying process. When such a fixed width is placed on the tip of the blade, it will cause great waste. On the other hand, some wind blade manufacturers lay the bagging film on mold first and cut it according to the size of mold, the rest bag film is used for the second laying. The cutting process wastes time and energy, and the rest materials are easily punctured and damaged when placed randomly.

At present, traditional cutting machines can only cut films with fixed width in one direction. Just like the films with fixed width and length that can be bought in the market. LEAP MACHINERY independently develop Nylon vacuum bagging pre-cutting machines, which can control the horizontal movement by setting the program, and cut the vacuum bag film with a specific shape to greatly reduce the production cost. Special customized pre-cut machines can work with spindles or without mandrel depending on specific application and accept different widths of spindles to reduce handling work.

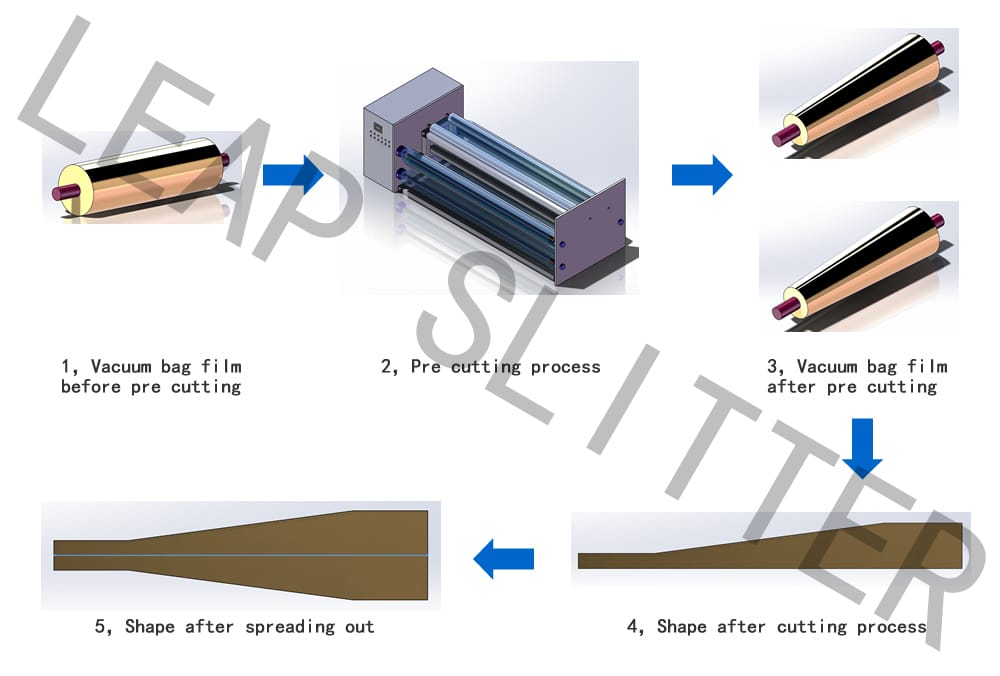

As shown in the figure above, first we cut a certain length of roll into two sets of rolls with cone shape, after expansion, the vacuum bag films completely fits the shape of wind blades. Because the shape of bag membrane is designed according to blades, there is no need to cut when customers start to lay it from the root of the blade. The rest of the bag film can be directly used for the second time with no waste.

After the production verification from wind power plant customers, the pre-cut equipment greatly improves the utilization efficiency and laying efficiency of vacuum bag film, avoids the damage caused by random placement of Nylon bag membrane, and the waste edge loss is greatly reduced.If you would like more information or assistance selecting or finding Vacuum bag film pre-cutting machines for your operation, please free to call the LEAP MACHINERY technical staff.

About Lvjie

Serch

Recent Posts

-

Overview of UHMWPE Separato... September 20, 2024

-

Overview of PVC Slitter Rew... July 2, 2024

-

Overview of Pre-coated Film... April 25, 2024

-

Overview of stretch film sl... March 11, 2024

-

Application of BOPP Tape Sl... November 29, 2023

Categories

- All Posts (28)

- Others (1)

- Unwinding Technology (3)

- Rewinding Technology (7)

- Slitting System (18)

- Control System (4)

Contact Info

Xiongzhou Street, Liuhe District, Nanjing City, 211511, China

Phone: 86 025 86555699Email: info@film-slitter.com

Recent Posts

-

Overview of UHMWPE Separato... September 20, 2024

-

Overview of PVC Slitter Rew... July 2, 2024

-

Overview of Pre-coated Film... April 25, 2024

-

Overview of stretch film sl... March 11, 2024

-

Application of BOPP Tape Sl... November 29, 2023